Brazilian Blowout Sues Oregon OSHA over False and Misleading Test Results

Suit Claims OR-OSHA Manipulated Tests and Wrongfully Promotes Fear Of Brazilian Blowout Product.port.

LOS ANGELES, CA, December 16, 2010

— The Company that does business as Brazilian Blowout, GIB, LLC, has filed a lawsuit against Oregon OSHA demanding that the agency stop reporting false and misleading test results about its popular hair smoothing product. The complaint says Oregon OSHA manipulated testing that wrongly asserts that Brazilian Blowout Acai Professional Smoothing Solution is unsafe.

The maker of the popular hair smoothing product says Oregon OSHA has done irreparable harm to the company and the professional beauty industry, including tens of thousands of hair salons and stylists, by distributing inaccurate product testing results and using improper testing protocol.

According to the complaint, Oregon OSHA wrongfully issued alerts after claiming to have measured high levels of “Formaldehyde” in product testing of Brazilian Blowout solution, when in fact they were measuring and reporting concentrations of a completely different substance called “Methylene Glycol.” That led to widespread media coverage and created unwarranted fears about the hair straightening product among hair stylists and customers across the country.

“Leading chemists agree that Methylene Glycol and Formaldehyde are very different, both chemically and physically. Methylene Glycol is a liquid; Formaldehyde is a gas that can be inhaled,” said Mike Brady, CEO of Brazilian Blowout. “Yet Oregon OSHA has inaccurately declared that these are “synonyms” even though these two substances have very different chemical compositions and belong to different chemical families.”

The lawsuit states, “OR-OSHA has engaged in activities that are unlawful, ultra vires, defamatory, negligent, and retaliatory in nature. As a result of these activities and the inaccurate, misleading, harmful, and prejudicial press releases by OR-OSHA, as well as its improper testing methodologies, GIB has lost sales, consumer goodwill, and industry market share.”

The complaint also claims that OR-OSHA misrepresented results of air sample tests on Brazilian Blowout, when in fact its testing showed air quality during use of the product was safely below OSHA limits.

Brazilian Blowout is demanding an injunction that stops Oregon OSHA from disseminating any further information related to the formaldehyde content of Brazilian Blowout or from claiming that the use Brazilian Blowout exceeds air quality standards. The company also wants the court to order OR-OSHA to remove from their websites damaging press releases, the “Hair Smoothing Report” and all other references to GIB or Brazilian Blowout. Brazilian Blowout also wants the court to order OR-OSHA to disseminate an explanation admitting to the inaccurate results and improper protocol used in the Report.

The results are in!

15-Oct-2010

EXPOSURE LEVELS TO COSMETOLOGISTS AND CLIENTS CONSIDERED SAFE FORMALDEHYDE GAS LEVELS ARE WELL BELOW OSHA’S PERMISSIBLE EXPOSURE LIMITS (PEL)

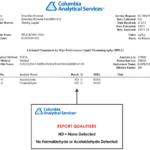

Independent salon air monitoring performed by one of California’s leading environmental safety companies has concluded that Cosmetologists exposure levels are more than SIX times lower than OSHA’s most stringent and conservative standard for air quality safety.

On October 9, 2010, the Air Monitoring Study was administered over an eight-hour period in a typical salon environment, while cosmetologists performed multiple Brazilian Blowout professional smoothing treatments throughout the day. The table below details the results of this scientific testing.

Test Summary: The breathing air (breathing zone) of two licensed cosmetologists was monitored while each performed two Brazilian Blowout Professional Smoothing Treatments in the same test salon, over the same eight-hour period. Their separate exposures to Formaldehyde gas in the air was determined to be 0.064 ppm and 0.073 ppm, which is well below OSHA’s most stringent requirements for an eight-hour period, called the eight-hour time weighted average (TWA).

What does this mean? The safest and most stringent level of exposure set by Federal Occupational Safety and Health Administration (OSHA) is called the OSHA Action Limit and is even more conservative than their “Permissible Exposure Limit” (PEL). The OSHA Action limit is 0.5 ppm, therefore, these two Cosmetologist’s exposures were more than six times below OSHA’s most conservative measure for safety where the potential for formaldehyde gas exposure is concerned.

Conclusion:These levels indicate that OSHA safe levels of exposure are NOT exceeded.

08-Oct-2010

The Oregon division of OSHA’s (Occupational Safety and Health Administration) recent claims that samples of the Brazilian Blowout Professional Smoothing Solution contained between 4.85% and 10.6% Formaldehyde has been proven to be incorrect.

Doug Schoon, a leading scientist and expert who works with state, federal and international regulators to develop beauty industry related standards and regulations with regards to ingredient safety, consumer testing and cosmetics registrations/regulations, says that the test methods used by Oregon OSHA do not properly measure Formaldehyde in water based cosmetic products. The tests conducted by OSHA actually measured a completely different substance called “Methylene Glycol,” and incorrectly referred to this substance as “Formaldehyde.” Methylene Glycol is the key functioning ingredient used in most professional hair smoothing treatments currently on the market.

Schoon reports the following:

Flaws in the testing methods used by Oregon’s division of OSHA actually cause the creation of additional Formaldehyde that is not normally found in the product, which led to Oregon OSHA erroneously reporting levels of Formaldehyde that cannot possibly exist in the product, especially given that Formaldehyde is a gas. Once again, what OSHA is actually reporting, is the amount of Methylene Glycol in the product, not Formaldehyde.

The only method that accurately measures Formaldehyde in water based cosmetic products is called “13C-NMR,” and OSHA did not conduct this particular type of testing. Had OSHA performed this test, they would have discovered that only tiny traces of Formaldehyde are detectable in these products, usually well below 0.0045%

EXPOSURE LEVELS TO COSMETOLOGISTS AND CLIENTS CONSIDERED SAFE FORMALDEHYDE GAS LEVELS ARE WELL BELOW OSHA’S PERMISSIBLE EXPOSURE LIMITS (PEL)